Best quality blow mold manufacturing with hyperMILL®

The CAM solution for high requirements of blow molding

Excellent high-gloss surfaces and flawless transitions in all details are important quality features of blow molds. A good CAM solution supports you to meet the high requirements.

hyperMILL® has been setting standards in the mold making industry for over 25 years and also offers a complete solution for blow mold manufacturing. From automation processes to data import to efficient programming to NC-Code simulation. Regardless of whether it is molds for the beverage and food, pharmaceutical, cosmetics or household goods industries – with hyperMILL® you always have the right solution to fully meet the high requirements. Thanks to customer-oriented development and close collaboration with well-known machine tool and cutter manufacturers, we ensure that hyperMILL® can continue to improve your processes in the future.

Specially developed CAM strategies such as 5‑axis radial machining and other innovative technologies make hyperMILL® the best choice for blow mold production. This way you are always one step ahead in the demanding competition of modern industry.

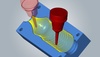

5‑Axis Machining: Bottle Mold

hyperMILL® offers strategies and functions to manufacture high quality bottle and blow molds. This demo part was machined with our partner Aura-Tools on a Röders RXP 601 DSH machine out of a aluminum block.

Features

hyperCAD®-S: Own CAD platform

Efficient roughing strategies

Precise rest material finishing

Specially developed finishing strategy: Radial Machining

Safe and reliable NC-Code Simulation

Brochure

Blow Molding.

hyperMILL® MOLD&DIE Solutions.

Complete CAM Solution for Efficient Blow Mold Machining

Advantages

- Powerful CAD Platform

- Efficient Roughing Strategies

- Precise Finishing Strategies

- Real NC code Simulation

- hyperMILL® AUTOMATION Center

Do you want to find out more about hyperMILL® for blow mold manufacturing?

For contact:

OPEN MIND Technologies USA, Inc.

1492 Highland Avenue, Unit 3, Needham MA 02492