F1 Subcontractor Bucks the Trend by Manufacturing a Mountain Bike

North Bucks Machining Ltd | Milton Keynes (Buckinghamshire), United Kingdom

As a child, Stewart Palmer was always more interested in dissecting his bike and finding out how it worked, rather than riding it. Now, as a highly skilled engineer, Stewart has spent the last 18 months designing and manufacturing his own downhill mountain bike.

Reflecting back on the early days of the business, Stewart says: “The business rapidly became successful in the 3‑axis machining arena but a contract to design and manufacture eight mould tools for 5‑liter Jerry Cans, meant we had to invest in technology. I previously worked at a prestigious company producing 5‑axis F1 parts, so my ambition was always to evolve into the 5‑axis market. This arrived in the guise of a Quasar 5‑axis machining centre from the Engineering Technology Group (ETG) and high-end CAM software from OPEN MIND Technologies. I had a great relationship with ETG; and from previously working with an F1 component manufacturer, I knew hyperMILL® from OPEN MIND was the only option with regards to CAM software.”

A biking enthusiast

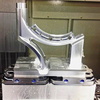

Stewart’s background in designing and producing complex parts soon gave the biking enthusiast the idea of designing his very own bike. The bike design consists of three core features, the main frame, the seat post and the swing arm that connects the main frame to the rear wheel and suspension. Using OPEN MIND’s hyperMILL®, the frame is machined in 40 hours, the swing arm in 18 hours and the seat post in 15 hours. To this end, hyperMILL® has genuinely been in a class of its own. As Stewart mentions: “The project wouldn’t have been possible with our previous CAM software. Without hyperMILL® and the 5‑axis Quasar, it would have been impossible. But what sets OPEN MIND’s hyperMILL® apart is its finish machining cycles. hyperMILL® automatically groups together the Z‑level finishing and ‘profile finishing’ cycles to blend perfectly between two surfaces and the two separate cycles. This is critical for our ambitions of the perfectly finished frame.”

Customer Testimonial: North Bucks Machining about their downhill bike

Stewart Palmer from North Bucks Machining talks about their CNC machined downhill bike and success with CAM software hyperMILL®.

“From previously working with an F1 component manufacturer, I knew hyperMILL® from OPEN MIND was the only option with regards to CAM software.”

Stewart Palmer, North Bucks Machining Ltd (NBM)

Taking Productivity to the MAXX

Whilst surface finish is more critical than cycle times, Stewart is aiming to reduce the machining time by implementing OPEN MIND’s new hyperMILL® MAXX Machining package for rough machining. Marketed by OPEN MIND as the next generation in CAM software for cutting hours from machining cycles, NBM has run tests of hyperMILL® MAXX Machining and found the cycle time reduction to be extremely positive. Just one of the roughing cycles on the main frame has been reduced from 2 hours 20 minutes to less than 1 hour 30 minutes, a 40% reduction. It is estimated that if the part was run on a machine with a spindle speed in the region of 15 to 18,000 rpm, as opposed to the existing 8,000 rpm, the cycle time is projected to fall close to 30 minutes, a massive 80% reduction on the existing run-time.

Customer Story

North Bucks Machining Ltd

Milton Keynes (Buckinghamshire), United Kingdom